FUERD is a fully functional and experienced aluminum die casting manufacturer in China. We are dedicated to manufacturing high-quality and reliable die casting tooling and aluminum die casting.

In more than 35 years of business, we have manufactured more than 10,000 unique molds. All our die and die-casting equipment are standardized on a global scale, and we coordinate mold resources on a global scale. This means that no matter where your manufacturing location is, we will provide you with support from concept, rapid prototyping, tooling and pre-production testing phases to full production.

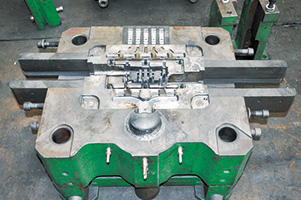

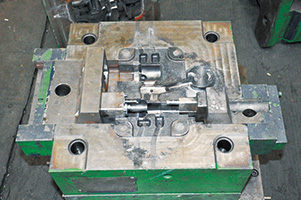

FUERD technically advanced facility, guarantees that a die cast die produced by FUERD exceeds your demanding requirements. Our many kinds of equipment is designed to handle the creation of robust dies that yield repeatable, reliable casting at your production facility. Base on our new machines preserve tight tolerances, less hand fitting is needed. The result is a better precise die with well interchangeability.

Die cast die from 180T to 2,000T in house die designs

TS16949&ISO 9001 Certification

FUERD experienced designer will work with you to create a tooling package that maximizes your process requirements, simplifies tool maintenance, facilitates quick die change, and ensures interchangeability of die components to save your time and cost.

|

|

|

|

|

Tooling designing |

CAD & CAM |

Mold maintenance |

Tooling maintenance |

FUERD sales, designer and program teams are focused on every phase of the project to make sure customer standards and specification are satisfied. Our attention to all detail and project management during the design and build phases of your tooling project maintains getting well PPAP and a successful product introduction.

|

|

|

|

|

Tooling drilling |

Compound Die |

EDM Mould |

EDM tooling |

FUERD quality management and committed support result in superior die performance and lower cost each casting over the life of the program. The added dependability of your manufacturing process transforms into well profits and good customer satisfaction.

|

|

|

|

|

Die casting mold process |

Die casting tooling wearhouse |

Tooling wearhouse |

Mold EDM |

Contact us for more information regarding our aluminum and zinc alloy die cast molds and die cast molds processes, or request a quote for further pricing details. We are an industry-leading provider of advanced die casting die and machining service.

|

|

|

|

|

Wire electrode cutting |

Mould CNC machining |

Mold polish |

Graphite electrode |

Tooling assembly

We can meet variable project demands without any delays, Send us your detailed aluminum die casting tooling request now

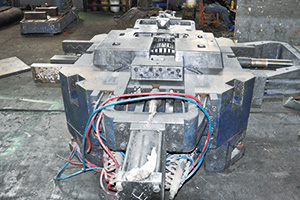

We have continuously improved our tools and machines to provide the most advanced die casting process. The multi-slider tool is designed to use four (or more) vertical sliders in the tool, allowing us to create more complex and accurate castings.

Multi-slide die casting has many unique advantages, including:

- Forming for the first time, eliminating secondary operations such as assembly and processing

- Complex geometries and strict tolerances can achieve world-class productivity and reduce overall costs

- Compared with standard multi-cavity molds, the difference between parts is minimal

- More compact tools, less prone to parting line changes and their negative effects on the dimensional tolerances of finished parts

Traditional die casting molds have a single cavity (one part per cycle) or multiple cavities (more than one part per cycle). Our conventional processing technology only designs two sliders instead of four sliders, which provides customers with production efficiency and lower costs.

WHY CHOOSE FUERD AS YOUR

DIE CASTING TOOLING MANUFACTURER

All our tools start with manufacturing design, and we talk with customers to ensure that any defects in parts can be reviewed and corrected before manufacturing tools. Modifying the mold features at the front end will help improve the final part, but it can also improve the overall quality of the tool. In this design stage, we can also predict the wear location of the tool and create a movable blade for the tool to save time and maintenance costs. The tools we designed can run with minimal downtime.

The tool department consists of approximately 25 tool manufacturers, 95% of which have served FUERD for more than 15 years. Their knowledge and experience have brought tremendous changes to our customers. Not only are they the best die-casting tools, but they also work with thousands of customers in almost every industry and can modify the solution when any problems arise in the production process.